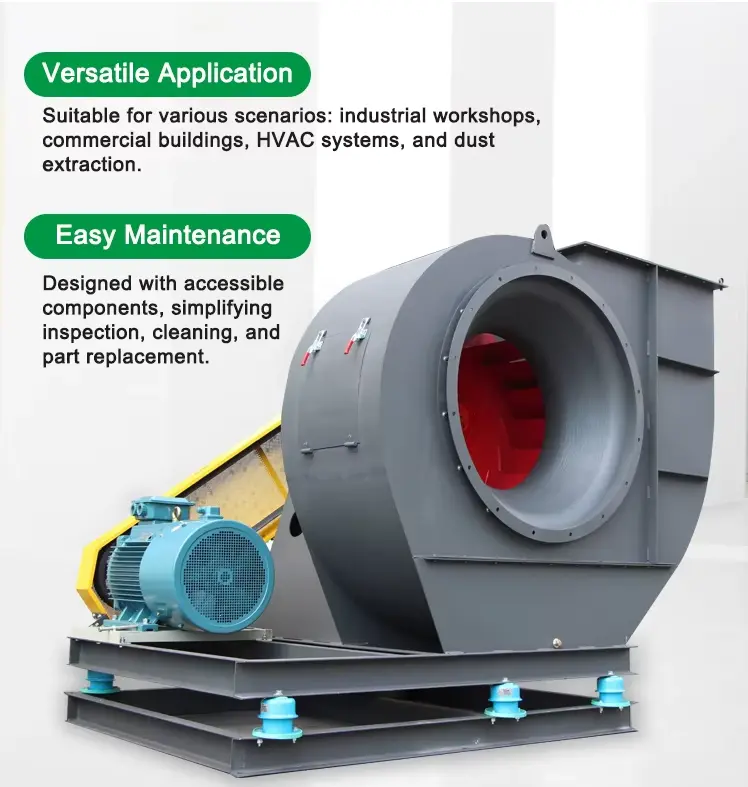

Power Plant Ventilation Fan produced by Hebei Ketong factory, mainly used for optimizing air circulation in power plant workshops, equipment cabins, and auxiliary facilities, as well as discharging high-temperature residual air, dust-laden gas, or mechanical exhaust gas generated during power generation processes, with outstanding ventilation efficiency and stable air volume control performance to ensure a safe and comfortable operating environment for power plant equipment and personnel.

It is generally installed at the air inlet of boiler auxiliary machine rooms, the exhaust port of turbine generator cabins, the ventilation outlet of coal handling system workshops, or the air exchange section of transformer stations, responsible for conveying fresh air into the plant area, and discharging high-temperature air, coal dust-containing gas, or equipment heat dissipation exhaust gas produced in power generation links such as coal combustion, steam circulation, and electrical equipment operation.

This fan is typically suitable for thermal power stations, hydroelectric power stations (for auxiliary workshop ventilation), auxiliary facilities departments at nuclear power plants, new energy generation enterprises (such as solar thermal power generation), or electrical equipment manufacturing and maintenance companies.

This Power Plant Ventilation Fan can effectively regulate the air environment in key areas of power plants, fully meeting the ventilation, heat dissipation, and dust removal requirements of power generation equipment and workshops, while strictly complying with the national power industry safety operation standards and industrial plant ventilation and air quality specifications.

|

GY4-73 |

NO. |

R/Min |

Pa |

m³/H |

KW |

|

8D |

1450 |

2104~1400 |

16156~30993 |

18.5 |

|

|

9D |

1450 |

2668~1775 |

23003~44128 |

30/37 |

|

|

960 |

1163~775 |

15229~29216 |

11 |

||

|

10D |

1450 |

3301~2194 |

31554~60533 |

55 |

|

|

960 |

1437~958 |

20891~40077 |

15 /18.5 |

||

|

730 |

829~553 |

15886~30475 |

7.5 |

||

|

11D |

1450 |

4003~2659 |

41999~80570 |

75 /90 |

|

|

960 |

1741~1160 |

27806~53343 |

22 /30 |

||

|

730 |

1004~669 |

21144~40562 |

11 |

||

|

12D |

1450 |

4777~3171 |

54526~104600 |

132 /160 |

|

|

960 |

2075~1381 |

36100~69253 |

37 /45 |

||

|

730 |

1196~797 |

27451~52661 |

15 /18.5 |

||

|

14D |

1450 |

6541~4333 |

86586~166100 |

280 /315 |

|

|

960 |

2831~1883 |

57326~109970 |

75 /90 |

||

|

730 |

1630~1086 |

43591~83624 |

37 /45 |

||

|

16D |

960 |

3709~2465 |

85571~164150 |

185 |

|

|

730 |

2133~1420 |

65069~124820 |

75 |

||

|

580 |

1343~893 |

51699~99178 |

45 |

||

|

18D |

960 |

4710~3126 |

121830~233730 |

280 |

|

|

730 |

2705~1800 |

92648~177730 |

132 |

||

|

580 |

1702~1133 |

73610~141210 |

75 |

||

|

20D |

960 |

5837~3870 |

167130~320160 |

||

|

730 |

3347~2225 |

127080~243800 |

220 /250 |

||

|

580 |

2104~1400 |

100970~193700 |

110 /132 |

||

|

22D |

960 |

6865~4864 |

233000~434000 |

650~850 |

|

|

730 |

3972~2815 |

177000~332000 |

310 /370 |

||

|

580 |

2501~1775 |

141000~263000 |

165 /180 |

||

|

480 |

1716~1216 |

116000~217000 |

140 |

||

|

25D |

730 |

5139~3648 |

260000~484000 |

570~700 |

|

|

580 |

3236~2295 |

206000~384000 |

280 /350 |

||

|

480 |

2216~1579 |

171000~318000 |

165 /210 |

||

|

28D |

730 |

6404~4541 |

365000~680000 |

1250 |

|

|

580 |

4040~2864 |

289000~540000 |

630 |

||

|

480 |

2775~1971 |

239000~446000 |

400 |

||

|

375 |

1697~1206 |

187000~352000 |

320 |

||

|

29.5D |

745 |

7218~5100 |

435000~810000 |

1250/630 /1250 |

|

|

596 |

4609~3236 |

348000~648000 |

800 /1000 |

|

Y5-47 |

NO. |

R/Min |

Pa |

m³/H |

KW |

|

4C |

3300 |

1922~1393 |

2751~5190 |

4 |

|

|

2900 |

1481~1079 |

2417~4561 |

3 |

||

|

5C |

2900 |

2324~1687 |

4723~8909 |

7.5 |

|

|

2620 |

1893~1373 |

4267~8048 |

5.5 |

||

|

6C |

2850 |

3364~2452 |

8020~15129 |

18.5 |

|

|

2620 |

2844~2069 |

7372~13908 |

15 |

||

|

8C |

2020 |

3001~2187 |

13474~25417 |

30 |

|

|

1860 |

2550~1853 |

12407~23404 |

22 |

||

|

9C |

1900 |

3364~2452 |

18045~34039 |

45 |

|

|

1800 |

3020~2197 |

17095~32247 |

37 |

||

|

12C |

1480 |

3628~2638 |

33318~62850 |

75~90 |

|

|

12.4C |

1480 |

3874~2824 |

36762~69347 |

110 |

|

Y5-48 |

NO. |

R/Min |

Pa |

m³/H |

KW |

|

4C |

3550 |

2221~1501 |

2932~5564 |

5.5 |

|

|

3150 |

1746~1180 |

2602~4937 |

4 |

||

|

2800 |

1377~932 |

2313~4388 |

3 |

||

|

2500 |

1097~742 |

2065~3918 |

2.2 |

||

|

5C |

3150 |

2819~1913 |

5304~9851 |

11 |

|

|

2800 |

2223~1509 |

4715~8757 |

7.5 |

||

|

2500 |

1769~1202 |

4210~7818 |

5.5 |

||

|

2240 |

1419~964 |

3772~7005 |

4 |

||

|

6.3C |

2800 |

3545~2403 |

9432~17516 |

22 |

|

|

2500 |

2819~1913 |

8421~15639 |

15 |

||

|

2240 |

2259~1533 |

7546~14013 |

11 |

||

|

2000 |

1798~1221 |

6737~12511 |

7.5 |

||

|

8C |

2000 |

3323~2253 |

13794~25619 |

30 |

|

|

1800 |

2686~1823 |

12415~23057 |

22 |

||

|

1600 |

2118~1438 |

11035~20495 |

15 |

||

|

1400 |

1619~1100 |

9656~17933 |

11 |

||

|

10C |

1800 |

4483~2958 |

22250~44634 |

75 |

|

|

1600 |

3531~2332 |

19778~39674 |

55 |

||

|

1400 |

2696~1782 |

17305~34715 |

37 |

||

|

1250 |

2145~1419 |

15451~30995 |

22 |

||

|

12.5 degrees Celsius |

1400 |

4234~2794 |

33800~67803 |

110 |

|

|

1250 |

3365~2223 |

30179~60538 |

75 |

||

|

1120 |

2696~1782 |

27040~54242 |

55 |

||

|

1000 |

2145~1419 |

24143~48431 |

37 |

|

GY6-51 |

NO. |

R/Min |

Pa |

m³/H |

KW |

|

8D |

1450 |

2745~1859 |

11000~26400 |

15~22 |

|

|

9D |

1450 |

3474~2353 |

15700~37500 |

30 /45 |

|

|

10D |

1450 |

4289~2905 |

21500~51500 |

45~75 |

|

|

11D |

1450 |

5190~3515 |

28600~68500 |

75~110 |

|

|

960 |

2275~1541 |

18900~45400 |

22 /30 |

||

|

12D |

1450 |

6176~4183 |

37100~89000 |

110~160 |

|

|

960 |

2707~1834 |

24600~59000 |

37~55 |

||

|

13D |

1450 |

7248~4909 |

47200~113000 |

185~250 |

|

|

960 |

3177~2152 |

31200~74900 |

55 /75 |

||

|

14D |

1450 |

8406~5694 |

58900~141000 |

250~355 |

|

|

960 |

3685~2496 |

39000~93400 |

75~110 |

||

|

15D |

1450 |

9650~6537 |

72400~172000 |

355~500 |

|

|

960 |

4230~2865 |

48100~115000 |

110~160 |

||

|

730 |

2446~1657 |

36600~87400 |

45~75 |

||

|

16D |

1450 |

10980~7437 |

88100~211000 |

500~710 |

|

|

960 |

4813~3260 |

58300~140000 |

160~200 |

||

|

730 |

2783~1885 |

44300~106000 |

75 /90 |

||

|

17D |

960 |

5433~3680 |

69900~168000 |

200~280 |

|

|

730 |

3142~2128 |

53200~128000 |

90~132 |

||

|

18D |

960 |

6091~4126 |

83000~199000 |

250~355 |

|

|

730 |

3522~2386 |

63100~151000 |

110~160 |

||

|

19D |

960 |

6787~4597 |

97600~234000 |

315~500 |

|

|

730 |

3924~2658 |

74200~178000 |

160~200 |

||

|

20D |

960 |

7520~5094 |

114000~273000 |

450~630 |

|

|

730 |

4348~2946 |

86700~208000 |

185~280 |

||

|

21D |

960 |

8290~5616 |

132000~316000 |

560~800 |

|

|

730 |

4794~3247 |

100000~240000 |

280 /355 |

||

|

580 |

3026~2050 |

79500~191000 |

220 |

||

|

22D |

960 |

9099~6164 |

152000~363000 |

710~1000 |

|

|

730 |

5261~3564 |

116000~276000 |

315~450 |

||

|

580 |

3321~2250 |

92200~219000 |

220 |

||

|

23.5D |

960 |

10380~7033 |

185000~443000 |

1000~1400 |

|

|

730 |

6003~4066 |

140000~336000 |

400~630 |

||

|

580 |

3789~2567 |

112000~267000 |

220~315 |

||

|

25D |

730 |

6794~4603 |

169000~406000 |

630~800 |

|

|

580 |

4289~2905 |

134000~323000 |

280~400 |

||

|

26.5D |

730 |

7633~5172 |

201000~483000 |

800~1120 |

|

|

580 |

4818~3265 |

160000~385000 |

400~560 |

||

|

480 |

3300~2236 |

132000~319000 |

220~315 |

||

|

28D |

730 |

8522~5774 |

237000~569000 |

1000~1400 |

|

|

580 |

5280~3645 |

189000~454000 |

560~710 |

||

|

480 |

3685~2496 |

156000~376000 |

315 /400 |

||

|

29.5D |

730 |

9460~6410 |

278000~667000 |

1250~2000 |

|

|

580 |

5972~4046 |

221000~530000 |

710~1000 |

||

|

480 |

4090~2771 |

185000~439000 |

400~560 |

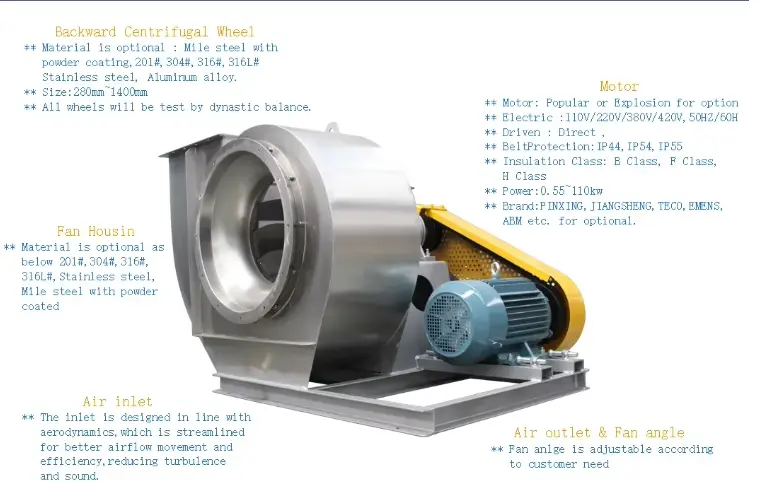

1.Advanced Impeller and Airflow Design:Impeller design is crucial for fan performance. Many models employ backward-curved blades to improve stability and reduce wear. Studies show that aerodynamic optimization, such as adding a central body at the impeller inlet, can improve total pressure efficiency by 5-10%, effectively optimizing the airflow inlet.

2.Optimized Housing and Inlet Geometry: The helical housing is specially designed for efficient pressure conversion. Special attention is paid to the inlet and housing "tongue" structure. Adjusting the initial tongue angle can improve efficiency by 2-3% while reducing flow separation at low flow rates, thereby expanding the stable operating range.

3.Durable Drive and Bearing System: This Power plant ventilation fan is designed for reliability, employing reinforced bearing housings and high-efficiency seals to prevent lubricant leakage. Furthermore, lubrication with machine oil (e.g., L-AN46) ensures stable performance even under continuous operation.

4.Energy Efficiency Under Different Operating Conditions: Power plant fans are designed for operation under high-pressure, high-flow conditions, but their energy efficiency targets are universally applicable. For example, even commercial high-pressure forward-curved centrifugal fans must operate within their highest energy efficiency range to avoid excessive power loss and noise levels.

Address

Changboluo Village, Siying Town, Botou City, Cangzhou, Hebei Province, China

Tel

For inquiries about centrifugal fan, blower fan, induced draft fan or price list, please leave your email to us and we will be in touch within 24 hours.